|

| September 13, 2016 | Volume 12 Issue 34 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

12 key factors in bellows design

The following items are 12 key ingredients in defining a custom bellows. Each must be specified before the design can be established. Be advised that the information provided here is only a guide, not an exhaustive design manual. Contact Servometer engineering for a review of your requirements prior to finalizing your design.

Typical bellows applications include: volume compensators, pulsation dampeners, actuators, electrical spring contacts, pressure switches and transducers, temp sensors and transducers, valve seals, expansion joints, linear multipliers, flexible shaft couplings, and more.

1. Stress Modes: Specify extension, compression, bending, swiveling, parallel-end offset, torque, and speed of rotation. Provide a drawing or sketch showing extremes of flexing where possible.

1. Stress Modes: Specify extension, compression, bending, swiveling, parallel-end offset, torque, and speed of rotation. Provide a drawing or sketch showing extremes of flexing where possible.

2. Quantify Flexing: Specify the maximum amount of stroke (axial compression or extension) and offset in inches, or bend angle in degrees, or by dimensions on a diagram.

2. Quantify Flexing: Specify the maximum amount of stroke (axial compression or extension) and offset in inches, or bend angle in degrees, or by dimensions on a diagram.

3. Pressure Differential: Specify pressure difference between the inside and outside of the bellows, maximum instantaneous pressure, and whether higher pressure is applied inside or outside the bellows.

3. Pressure Differential: Specify pressure difference between the inside and outside of the bellows, maximum instantaneous pressure, and whether higher pressure is applied inside or outside the bellows.

4. Rigid Stops: Specify whether rigid stops will limit the extension or compression of the bellows to its rated stroke, or if the bellows will be required to withstand pressure unrestrained. A restrained bellows usually provides better performance because it will continually operate within the design parameters.

4. Rigid Stops: Specify whether rigid stops will limit the extension or compression of the bellows to its rated stroke, or if the bellows will be required to withstand pressure unrestrained. A restrained bellows usually provides better performance because it will continually operate within the design parameters.

5. Spring Rate: Specify the required spring rate in lb/in., or conversely, the amount of force available to flex the bellows the desired amount.

5. Spring Rate: Specify the required spring rate in lb/in., or conversely, the amount of force available to flex the bellows the desired amount.

6. Life Cycles: Specify the required useful life of the bellows, expressed as the number of flexing cycles. Define the flexing cycle.

6. Life Cycles: Specify the required useful life of the bellows, expressed as the number of flexing cycles. Define the flexing cycle.

7. Temperature Extremes: Upper and lower extremes of temperature should be indicated.

7. Temperature Extremes: Upper and lower extremes of temperature should be indicated.

8. Exposure: Indicate the media (liquid and/or gas) to which the internal and external surfaces of the bellows will be exposed. Identify any potentially corrosive conditions or agents.

8. Exposure: Indicate the media (liquid and/or gas) to which the internal and external surfaces of the bellows will be exposed. Identify any potentially corrosive conditions or agents.

9. Assembly Method: The method to be used to join the bellows to end fittings, such as soldering, brazing, welding, cementing, should be specified.

9. Assembly Method: The method to be used to join the bellows to end fittings, such as soldering, brazing, welding, cementing, should be specified.

10. Vibration: Specify vibration or shock conditions that the bellows will experience.

10. Vibration: Specify vibration or shock conditions that the bellows will experience.

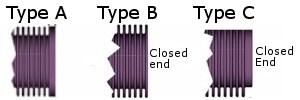

11. End Configuration: Specify types and lengths of the bellows ends. "A" ends are most economical. All Servometer stock bellows have two "A" ends.

11. End Configuration: Specify types and lengths of the bellows ends. "A" ends are most economical. All Servometer stock bellows have two "A" ends.

12. Geometric Constraints: Specify restrictions on size of bellows, i.e. maximum O.D., minimum I.D., maximum overall length, etc.

12. Geometric Constraints: Specify restrictions on size of bellows, i.e. maximum O.D., minimum I.D., maximum overall length, etc.

To submit your electrodeposited nickel bellows design, complete Servometer's Custom Bellows Design Form.

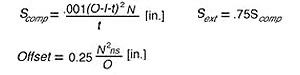

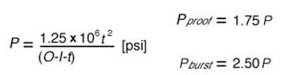

Symbols to use for design specs

O - Bellows outside diameter, in.*

I - Bellows inside diameter, in.*

t - Bellows nominal wall thickness, in.

N - Number of active convolutions in the bellows

E - Young's modulus. Ref. 23.35 x 106 for Servometer electrodeposited nickel

S - Maximum permissible bellows stroke, in.

s - Maximum permissible stroke per convolution, in.

n - Length of one convolution (pitch), in.*

L - Bellows convolution length

P - Pressure (differential) rating, psi

A - Angle subtended by bellows bent in circular arc, degrees

R - Bellows spring rate, lb/in.

r - Spring rate per convolution, lb/in.

* There are limited ranges of tolerable values for the I.D./O.D. ratio and pitch, based upon production factors and bellows performance. Contact Servometer engineering for details.

Source: Servometer

Published September 2016

Rate this article

View our terms of use and privacy policy